- #Calculating flexture modulus how to#

- #Calculating flexture modulus full#

- #Calculating flexture modulus iso#

Selection of filler majorly depends on its aspect ratio and particle size. Since the physical properties of many materials (especially thermoplastics) can vary depending on ambient temperature, it is sometimes appropriate to test materials at temperatures that simulate the intended end use environment.įlexural Modulus – Impact of Fillers and BlendsĪlso, addition of fillers increases the stiffness or flexural modulus of a polymer system, especially polyolefins ( PP, TPOs…). If the specimen does not break, the test is continued as far a possible and the stress at 3.5% (conventional deflection) is reported.

#Calculating flexture modulus iso#

For ISO 178, the test is stopped when the specimen breaks.For ASTM D790, the test is stopped when the specimen reaches 5% deflection or the specimen breaks before 5%.ISO 178 standard describes a similar method for determining flexural properties. The data is useful for comparing the strength and stiffness of different plastics when a load carrying part is subjected to bending in service. The values are significantly different from the tensile modulus because the stress pattern in the specimen is a combination of tension and compression. These are specifies methods for determining the flexural properties (bending properties) of reinforced and unreinforced plastics and electrical insulation materials. Ofcourse there exist several other methods as well as listed below, but they are not discussed here. Most commonly used standards to measure Flexural Modulus are ASTM D790 and ISO 178.

#Calculating flexture modulus how to#

How to measure Flexural Modulus (Stiffness)? » Flexural Modulus Values (GPa) of Several Plastics » Factors Affecting Flexural Modulus and Impact on Other Mechanical Properties » How to Calculate the Flexural Modulus of Plastic

#Calculating flexture modulus full#

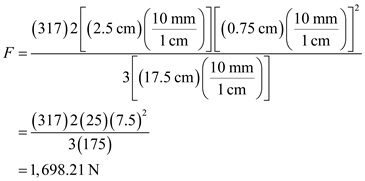

The strength increases are 43.46% and 85.57% when compared with those of the full carbon and glass configurations respectively. The overall maximum hybrid effect is achieved when the hybrid ratio is 0.125 () when both V fc and V fg are 50%. A general rule is in order to improve flexural strength, the fibre volume fraction of glass/epoxy plies needs to be higher than that of carbon/epoxy plies. Utilisation of hybridisation can improve the flexural strength. Flexural strength increases with span-to-depth ratio. A simple mathematical formula was developed for calculating the flexural modulus of hybrid composites, given the moduli of full carbon and full glass composites, and the hybrid ratio. It is shown that flexural modulus increases when the span-to-depth ratio increases from 16 to 32 but is approximately constant as the span-to-depth ratio further increases. The validated FEA model was used to study the effects of fibre volume fractions, hybrid ratio and span-to-depth ratio. For the purpose of validation, specimens of selected stacking configurations were manufactured following the hand lay-up process and tested in a three point bend configuration. The three point bend test in accordance with ASTM D790-07 at various span-to-depth ratios was simulated using finite element analysis (FEA). A study on the flexural behaviour of hybrid composites reinforced by S-2 glass and T700S carbon fibres in an intra-ply configuration is presented in this paper.

0 kommentar(er)

0 kommentar(er)